1978 thru 1982 UFIX coal hoppers an engineers nightmare in Tales of the Jointed Track

- April 10, 2015, 8:55 a.m.

- |

- Public

UFIX what does that mean? It was reporting mark ie; UFIX 223579 UFIX was the owner of the car. U= Utility F= Fuels I=INC X= leased Utility Fuels Incorporated..and they leased the cars. These operated on what we on the old Santa Fe and/or Joint line called the Houston Coal trains . They were at Smithers Lake, TX north of Houston.

The Smithers Lake utility was a big major coal fired plant. They had three fired plants. Two were on line generating electricity, one was down for maintenance. They rotated each one so, you Texans had power. In my time of railroading, we had 30 train sets.

These cars were 130 ton capacity hoppers … BethGONs they were in the railroad vernacular bathtub hoppers. WTF is a bathtub hopper? They are rotary dumped, with a belly between the trucks, that added 50 more tons of coal. The air braking system was unique, and supposed to be better, but it was not.

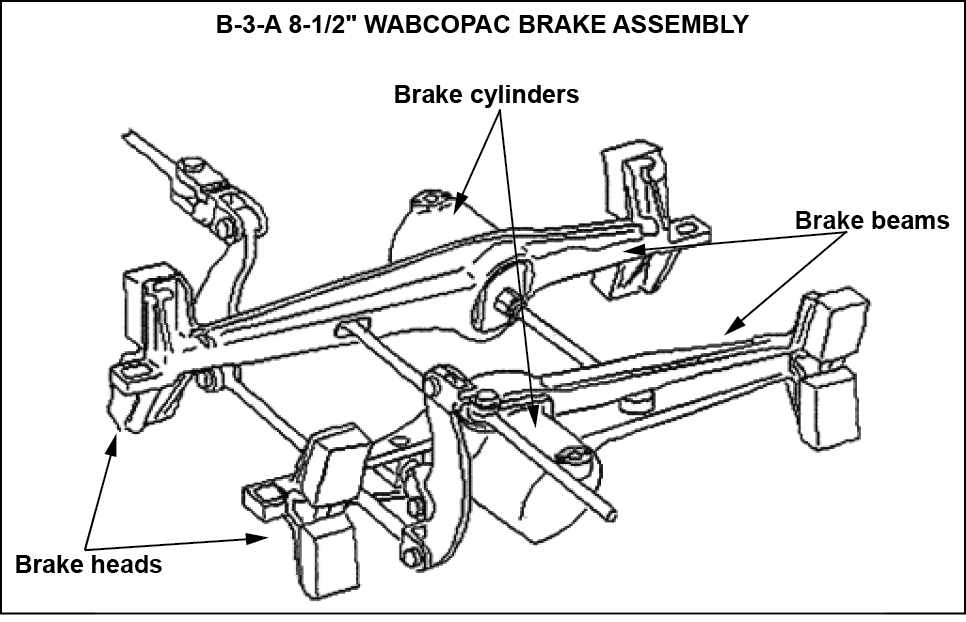

Air Braking 101.1: These had individual truck braking. Meaning each truck has a brake cylinder that activated, when the application was made. It was not on the rod and lever design, and “one” brake cylinder to apply the brakes .

a schematic drawing of the truck mounted air brake cylinders

You may say yes…a good idea… but it had problems.

Like all air braking systems, what are your parameters? Brake shoe tolerance, need to be changed out or adjusted ? Slack adjustment ? Is it automatic or needs manual adjustment? Or both ?

Air braking via the control valve. Will this maintain and hold the set, as needed? Will and can it hold and maintain a reapplication, without causing an undesired release. These early ones, no they failed on many areas. After numerous complaints , the car builder, the air brake manufacturer, and the BN and Santa Fe addressed the concerns .

The control valve is your operational piece of the equation. It takes and responds to the pressure changes in the brake pipe. Air pressure opposing air pressure, that’s the simple explanation on why the train air braking system works. Each truck had two brake cylinders on opposite ends and when the air was set and fed to the cylinders. they forced the brake shoes to the wheel tread.

A railroad car control valve. Service portion, Pipe bracket, Emergency Portion

These cars had a propensity to act odd. Some were found to bleed off a set, meaning..the set was made. Pressure maintaining kept leakage to tolerance, and they should remain applied, but for some reason, some would arbitrarily release.

Undesired releases were also common with these cars. You made a set, then trimmed with the the dynamic brakes on the locomotives. All is good in engineer land, yeah in the perfect world. Okay all those dynamic brakes work and operational ? Reported and tagged…or maybe not. So you make a set, and they are digging in harder than you wanted. Me off the top at Palmer Lake, get to 7 to 8 mph and take a minimum reduction, split the reduction to 10 lbs total, and let the train do the braking. Trim with the dynamic brakes and all is good. You can make a stop at Monument if needed, Academy, the “Springs” ad nausea.

You have that first set, they are grabbing, the signal at 54.5 is clear, your going through Monument siding. They start stalling, more than wanted at 56.2, and you are forced to release ‘em. No problem, bring it to 12-15 mph make the release, you’ll get a good charge, then at Baptist Road MP 58.1 into the reverse curves at 58.7 to 59.1 it levels and the curves also aid in the braking. Then the shhhhht, hissed from the brake valve. The dials drop on the brake pipe side 2 lbs. Then the air equalizes, and it goes to the original set off the brake valve.

Okay what just happened? Well a set was made back, and the partial charge was not enough to make up for the last reduction. I usually went 2 lbs deeper on the next one, but with these cars, never enough. The air, as it reduced through the brake pipe, will equalize. Then, as pressure maintaining comes in, it should hold the set, but there is a “false” brake pipe. Something in the train says, I am at this reduction, and the brake pipe is at this reduction. When equalization is finally reached, the valve says this. (PSST they don’t talk) I went from a release and getting charged to 90 lbs. Oh another reduction, okay…80 lbs..lets set, air to the brake cylinder. I’m 80 cars or more deep, and I respond to your set. The air sets, and all is well, but then this last reduction wasn’t deep enough to cover the last set and recharge. The brake pipe as it equalizes, causes a false reading, and I am lower, but I am not. Oh a rise in brake pipe pressure, and with these new control valve they do two things. A rise of 1.5 lbs will trigger a release, and the Emergency Reservoir will add a little air to help recharge the brake pipe quicker, and now its propagating, the release.

New air brake control valves, this too is a learning curve. Accelerated release, does two things in the air brake and train handling world. First it gives a faster propagation of the release of the air brakes. In the old days…and I was on the border of older and newer equipment in my railroad days, the old AB Control valve, functioned but it was slow, and releases, held on and you had to watch speed, terrain, and grade to be effective. Yes, these still play an integral part, but again a 50 to 60 car freight was big. Now tonnage, and longer freights are the norm. Yes, you are required to take ‘em all on. Most trains now are in the 85 to 130 car range. There is DP, that helps, but they are big and again you need to know where yer at. Signal indication, going in?, down the main and stop, running meet ? pacing on the block of the train ahead. Making speed, or under powered and is overtaken?

Second, accelerated release can and does dump a lil Emergency reservoir air into the brake pipe, to accelerate charging of the train.

QUIZ!!!.. After the brake pipe is charged, what charges first, The Emergency Reservoir or the Auxiliary Reservoir ? Hands? The lil white haired girl in the back!

What?? Yes correct , the emergency reservoir. Then the auxiliary will begin its charge.

The New York Air brake and Westinghouse people were called in to address concerns. Two things were realized, the reapplication was not made deep enough, to stop the undesired release. So if you took the initial reduction, added 3 more lbs for a 10 lbs set, and rode it out, till you needed a release. You are playing the sags and the territory, and the next set you make, a descent blow of exhaust, but did you bring it to at least a 12 lbs reduction? If not you may get an undesired release.

The other problem were the truck mounted air brake cylinders. It was found there were leaking seals within the brake cylinders that held and applied the braking to the wheels. Train sets were taken out of service, and retro fitted with new kits and cylinders.

Pueblo, Colorado July 1982

I had the Road foreman with me, riding on a trip south to Pueblo. We were placed in the Hump, and told Hump 2, cut to clear, power to the fuel track. There was a UFIX, Houston symbolled train on the main. We were about 12 to 15 feet lower in places till the hump tracks paralleled the main line at grade. Dennis, lets look at this train here, waiting for a rested crew. To his shock, even and a good set, and handbrakes applied, the amount of cars that went to a release position, although a set of the air was still there. Out of 130 cars we counted 35 that released. That was another shot across the bow, and we were not making up these problems.

Resolved, repaired, and back in service. There were 31 train sets at that time, and it took time, but you knew when the repaired sets were in that train. What a difference.

Last updated April 11, 2015

MageB ⋅ April 12, 2015

Wow....I'm sorry, that seems really dangerous stuff. What a story you tell.

ChallengerSeven ⋅ April 12, 2015

Are the UFIX cars still in service, and are there other reporting marks they were/are used under? I'll look for 'em the next time I'm on I-25.

Brakeshoe Bob ChallengerSeven ⋅ April 12, 2015

I think they have either been scrapped or have been bought for scrap and tie hauling. Before I retired, I noticed some up at the Steel mill, hauling scrap and some were set over to be cut up. I know the utilities have been going to the lighter Aluminum hoppers