Broken rails, compromised track, and other tales Part 1 in Tales of the Jointed Track

- Feb. 19, 2015, 8:58 p.m.

- |

- Public

Derailments, they are costly, not only to the railroad, but to the towns and cities they provide service to.

As a retired railroad locomotive engineer, and a former Company officer, it has never been the intention of the railroad to quote, blow up your town. Derailments are costly, not only on the Company side, but whatever collateral damage that exists.

Here are a few examples of broken rails.

This looks like this broke during severe cold and while a train was traversing it. You can see the rail anchor and spikes still holding it in place. Trains could be walked over at 5 mph under the supervision of the Signal maintainer and/or track supervisor. This triggers several things. This will trigger a shunt in the block signal system, causing signals either side to display red. In CTC a “Code Brown will generate on the DS screen, signalling an occupied block, although no trains are in the area. This usually shows up right after the train in question passed and the route does not clear.

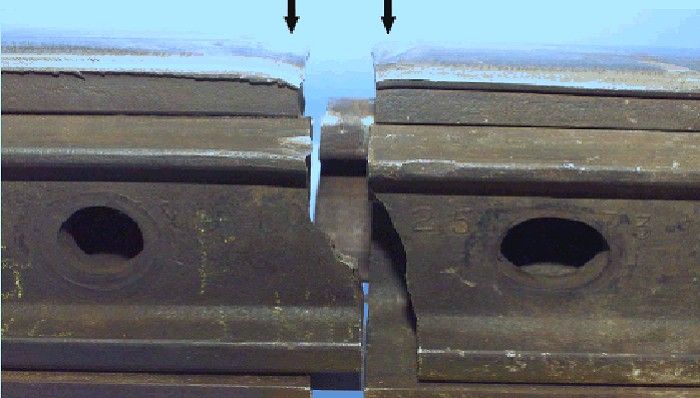

You can see not only the rail had broken, but fractured the angle bars as well. This can be caused by bad ties and a compromised roadbed. This will stress or place stress and it is concentrated on a certain part of the track structure causing it to fail. These are common breaks found in rail yards.

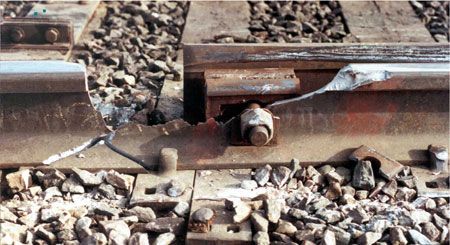

You can see the rail here is broken, under a locomotive. They will have to walk it over and change it out or place a temporary angle bar repair to get the train over and replace the rail. The “I” looking image just to the right of the break, is where the rails were welded together. You can see the Silver looking material, by the break. That is a fresh break and the rail has snapped. Fatigue here could be caused by the manufacturing process. I am sure a full report was made and a sample of the rail would be sent to Mill and to the railroad metallurgical department for assessment. If the batch has been flawed these rail from this batch will all be changed out.

This photo has shown a really bad chunked out break enough said I suppose

looking at the photo this was in and near a switch.. You can see the guard rail, just behind the break .

Last updated February 20, 2015

ChallengerSeven ⋅ February 20, 2015

Those are some amazing pictures, and it's remarkable the stresses that rail has to endure.

I knew a guy who worked as a brakeman during World War II.

He said that, one night, he heard a 'bling-bling...CHUNK-CHUNK' from way down in the yard, and it'd happen again and again as the cars were being humped.

Turns out it was the broken top of the rail that would go 'bling-bling' as the first set of truck wheel went over the break, and 'CHUNK-CHUNK' as the rear set of wheels crossed the gap where the top of the rail had been knocked off!

According to him, the railroad didn't want to hold things up to repair the rail, so the brakeman would manually replace the broken part into the break on his way back.

MageB ⋅ February 20, 2015

Those photos leave me speechless. Reading on...

Larry ⋅ February 21, 2015

One time Amtrak No 3 reported to me that upon stopping at La Junta, Co the Engr found a chunk of rail about 10 inches long on the locomotive steps. As a dispatcher that was bad news for sure as now I had to get someone out to go inspect everything behind this train. Anyway after things settled down nothing was found. Perhaps a trespasser had found the rail along the track and placed it

on the steps. Broken rails are usually going to cause problems during the first

cold fronts come thru in the early winter. Stan Coleman was the engineer whom I first worked with out of Winslow, Az and he had went over to Amtrak first working

Amtrak between Albuq and Needles. Then years later I was working the La Junta Sub and I'll be ole Stan called me and ask Larry is that you. Yep I said I changed

territory also. I could always count on Stan as he could always find the means to keep his train on time even if they had some short delays here and there.

Brakeshoe Bob Larry ⋅ February 22, 2015

A good hogger who pays attention and is not a whiner is a good asset, because they will rumble when they are able.

I had an incident like that

The Ast Brothers and the three coal empties north in Tales of the Jointed Track

Sept. 28, 2014, 8:11 a.m.

Doug Deaton when they dispatched out of la Junta Broke it off in 'em