Corridor mentor Denver Terminal The loose injector at 38th St. in Tales of the Jointed Track

- Nov. 2, 2014, 6:52 a.m.

- |

- Public

There were two trains in the coal tracks. They were southbound, and called on duty. One was a loaded coal train. the other a grain train. I talked to both engineers and told them consider me attached, and working the DP’s. The load was on duty first, so I’ll get that done first. Nothing to write home about, everything was like it was supposed to be. I heard the crew, on the load, called the engineer and reported all signed, and good. Fuel readings were relayed and I was off and clear.

I am walking around the grain train. I am getting whiffs of raw diesel fuel now and then. There are two units on the back, and there will be a manned helper, that will pick them up at Big Lift.

The DP “link”, was a GE C-44, an older 4100 series, unit. Probably about 4 years old. The other was an EMD SD-60, looks like it was brought out of storage, and ready to be utilized to the maximum. The water level on the “60”, was in range, “full when running”, the color was a bright, deep Fuchsia tone and clear in depth. They must have brought the Borate level up, and there is no signs of fouling.

In the cab, the “crude” diagnostic computer has a message up. I push the button, Code ( numbers)....Grid fault fail. No dynamic brake. Well it wasn’t tagged, what else is new.

Diagnostic computer on SD60-60M GP60-60M and 60Mb units

It is also Isolated, meaning, it is “offline”, and just like a boxcar. Someone was back here, to silence the alarm bell. It still shows that the dynamic brake is still activated. Not tagged, yeah let it be someone Else’s problem.

SD-60 MAC SD-70MACE dynamic grid assembly. The photo below is the blower fan which forces cooling air up and through the grids

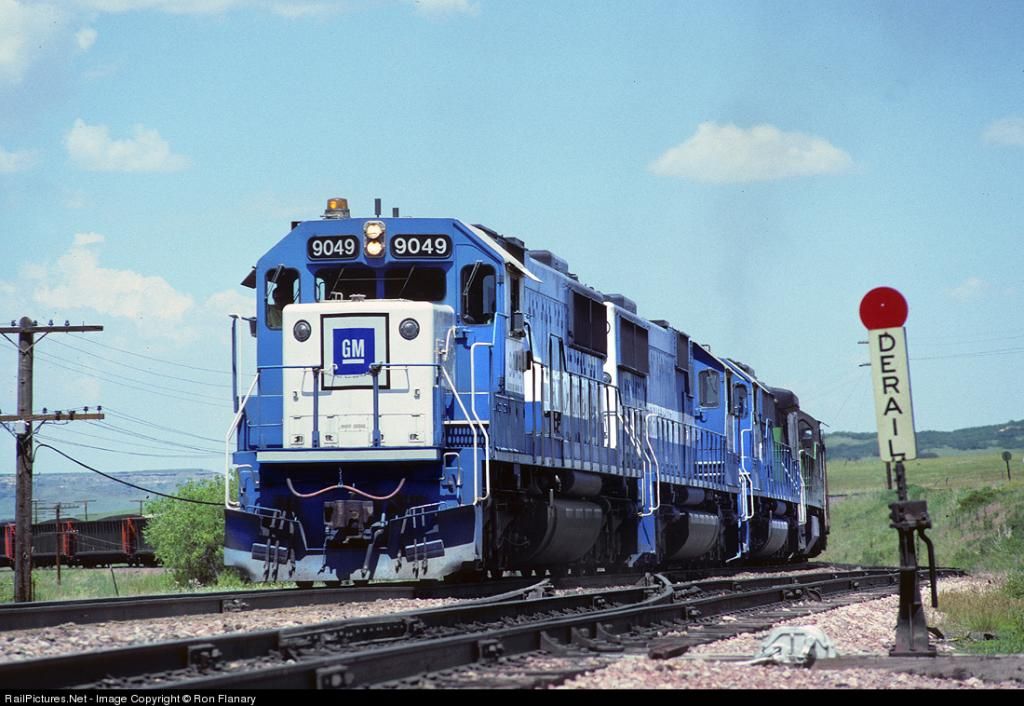

A typical OWY leased SD-60 when they were new. This is the “last curve” The head end is a quarter mile from the summit at Palmer Lake. The helper crews would call out last curve, and we’d start the throttle down and make the cut-off. The cars in the background are UFIX hoppers for Houston ( Spring, TX) Utility. Utility Fuels Inc.

It won’t affect horsepower, it will produce that, just the “retarding brake”, will not function. This is not the “Train braking system”, that is pneumatic, this is electrical. In dynamic braking, the traction motors, are reconnected, via circuits, to become a generator. So the faster the armature spins, the electrical energy produced causes a drag on the rotation. This can be regulated, by the engineer, in conjunction with the train air brake. The electricity produced, is dissipated thru a fan blown grid system. Like a 280 ton toaster on wheels. Grid failure, could be that, a short in the grids itself, or a bad high voltage relay, or maybe the 36 inch grid blower fan. The shop will have to investigate. I look to see if there is a notation of a traction motor(s) picking up ground relay. No, clear all the way to the end of the log. I place it on line, cut out the dynamic brake circuit, write a tag out. I’ll call it into the NOC as soon as I work the C-44.

Typical BNSF 4100 series locomotive

I check out the GE, look at the water level. It too, is in operating range, “full at Idle”. But there is a strong smell of fuel. I shine a light around, cant see a spray, or a pattern, from a ruptured or leaking injector line. I go to the other side, open the hood doors nothing, but these is some pooling. Back to the other side, and bingo, near the Main Generator end, a small liquid trail, on the catwalk. I open that hood door. Yep there it is. The number 5 injector, has broken free, and is moving up and down, with the combustion cycle. Since it is a diesel, it is not firing off, and the piston is blowing the raw fuel out the hole that the injector should be in.

Although this is a diesel engine taken out of the locomotive. The top most object is the injector. If you count from the “far” end five in that was the offending cylinder. The Flywheel area…that is where the main generator will be placed and bolted in. The object far right is the Woodward governor and its stuff. This (engine and governor) will probably be sent back to either Topeka Shops ( former Santa Fe) or West Burlington (former CB&Q/BN) for rebuild overhaul and re installed in another locomotive.

I call the crew, and said we a few problems back here, I’ll let ya know. I call the yardmaster at 31st ST and inform him of the situation. “Can it leave town?” “NO, unless you want to call the fire department”. “The roundhouse needs to see if they can repair on site, if not, you need another locomotive”.

That set real well, I get into the cab and isolate it, and wait for the roundhouse. I access the diagnostics switch, and go to the computer access screen. This series of units have them on the back wall by the circuit breakers , and Traction Motor cut-outs. I see an auto-traction motor cut out. The number 5 motor, nothing else, no ground relay or ground relay lockout. It isn’t tagged. It tripped somewhere out on the plains en route to Denver. Plus, unless it sent an alarm, to the head end, it worked into town. The last inspection was Funk, NE a day and a half ago. I call NOC Mechanical, they answer the radio page quickly. The information was relayed about the No. 5 injector, and that the roundhouse is en route to see if they can repair.

Then I told them about the auto TM cut lout logged on the computer. I am told to code this number in, and relay the information. A lite load resistance, across the armature. No lock out, no ground relay. I was told to tag it and physically cut out the number 5 motor.

Traction Motor cut out switches

It will operate at full horsepower, and the computer will automatically distribute it equally across the remaining traction motors, and dial back as need. The SD-60 is reported to them as well, so these defects will show up in the “L” Inquiry, when it gets to the next shop.

The dynamic brake will operate as well, but only 5 axles. So calculating, the total dynamic braking effort, even though those units are all 6 axles, the dynamic braking is equivalent to 21 with the lead two and the C-44, on the DP consist, we’ll have 5 actual on the C-44, and the SD-60 has a bad order dynamic brake.. The tonnage is at 13,750 tons, and the Ton per Operative Brake (TOB) says need 16 dynamic axles. We meet that for the descent to Colorado Spring. 13,500 tons divided by 125 cars is 108 TOB The chart says 12,001 to 14,000 tons TOB 106 to 115 the table says 16 operative axles of Dynamic braking.

TOB is the gross trailing tonnage divided by total number of cars, that have an operative brake. Remember, all have to be cut-in and operational, for the air test and leaving the origination terminal.

Jimmy Decker shows up in the roundhouse truck. He’s the day machinist, and has his wrenches and an injector tool. “Jimmy I’ll show ya over here on the engineer’s side”. “Yeah, it’s loose”, he chuckles. I ask,”Ya need to shut-down the diesel? I have the crew on the lead, in case the “link” breaks on the re-start”. “Nah, I think I can get it, I need you to push the injector into the hole, in the cylinder liner, if I can get it to catch, we’ll get it tight”. “Okay, ya think, we ruptured a fuel line or fittings?” “Nah it’s pretty slack, I’ll check if this works”. Well the injector is seated, I can feel the pressure trying to force it out, Jimmy tightens it into the cylinder. The lines and fittings are checked, no leaks. Jimmy does an injector pop test. The computer cuts each injector, then loads it with a little extra fuel, and there will be a distinct POP when it fires off. Our offending number 5 cylinder pops off like a champ. Jimmy says I have some, dry soak, and will place it on the catwalk, and in the engine room. That’s taken care of. A half full trash bag, will hold the sweepings, and Jimmy will take it back to the house.

I thank Jimmy, and make sure he’s clear. I call 31st, Steet and say that machinist and I are both clear. I detach with the crew, give them fuel readings, and about the SD-60 having no dynamic brake and I tell him about the number 5 traction motor being cut-out and tagged. “It’s reported to Mechanical at the NOC, and they have given the all clear. The Traction motor lock up Lock out circuit is active, so if there is a problem, it will send an alarm”. “OK”. “You have enough axles to get to the Springs, but you can have the Helpers assist ya down, if you request it” “Nah, we’ll be alright, thanks for the help”.. “My pleasure, mentor detached”. On to the next adventure.

Last updated November 24, 2018

Loading comments...