Goddamn This Yard Stinks !!! in Tales of the Jointed Track

- May 25, 2015, 11:43 a.m.

- |

- Public

That was a story from Van Hargrove, a Cajun I worked with. This occurred in Temple, TX.

Sometimes yer Co-workers whether trainman, switchman or engineers, could be horses-asses. The grit in the well oiled machine.

I have worked with yard crews, that can read a list and like an orchestra, bang ‘em out and get the job finished. Then crews that couldn’t pour piss out of a boot with the instructions on the heel. There were yard engineers as well, who were lax and poor handlers. They missed signals, made rough joints (couplings) and a general pain in the butt, to work with.

Van worked the yard in Temple, as a switchman and / or switch foreman, by choice certain times of the year. He held seniority to Houston - Galveston, on the Galveston Subdivision and to Silsbee, TX, via Sommerville on the Conroe Sub. He could go west to Sweetwater, TX via the Lampasas Sub.

The yard jobs for engineers were seven day a week jobs. I was forced to Pueblo Yard in my early career, and was on the tail-end of the seven day assignments. Van worked this assignment, with this particular engineer, two days a week, on the second trick (afternoons). This engineer, was a terrible, nasty person. Cranky, disagreeable, and a terrible engineer to switch with. Van and his switch crew broke it off in this guy, and he was much more courteous and compliant, when he switched with them after that.

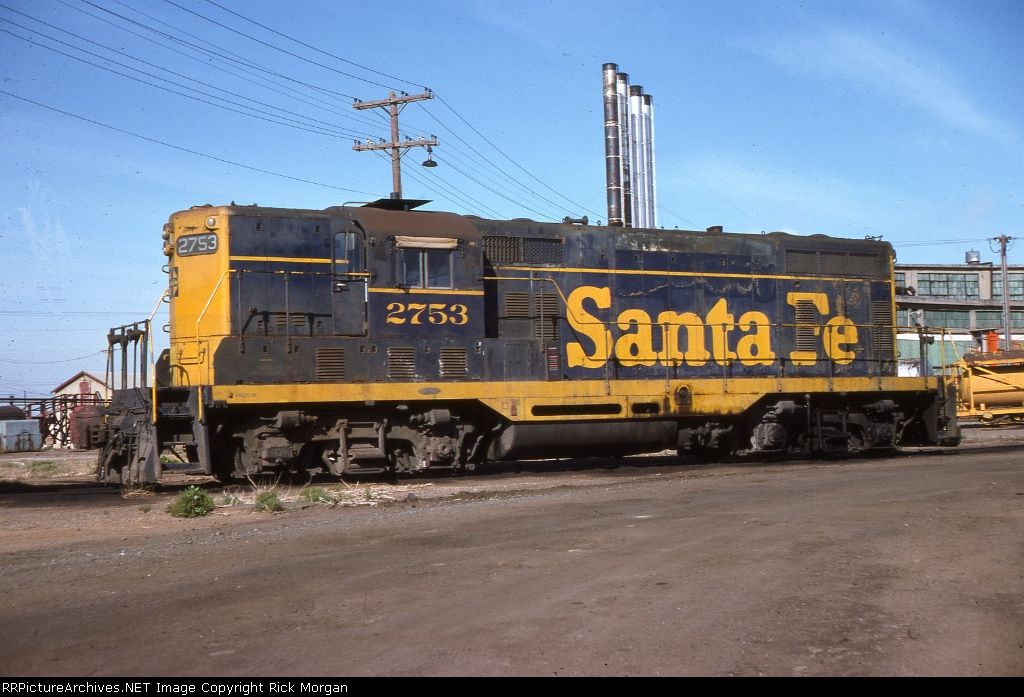

A GP-7 used in local and switch service in Temple Yard

What started it, was two things. When this engineer relieved himself in the yard, instead of going on the ground and doing business. Let’s be crass, and pee on the grab irons and on the steps. Even with gloves on, who wants wet gloves with urine on ‘em? Words were spoken, and Van being Cajun wasn’t too polite in the exchange.

The other thing was he wasn’t taking the signals for car counts, and easy signs for slowing and stopping the cut, for switches and coupling into cars. Van and his crew had enough and its time for a few lessons.

The yard is dark, and the lanterns are out. Van shout up to the open cab window. “Ya have 20 cars, we need to shove deep, and make a joint. We’ll pull ‘em out an switch this list”. A grunt of disgust, came from the darkened cab. The field man swings a go ahead and boards, the rear car. Being dark, his light is the engineers “brain” for the move. He clips the lantern to the end ladder and gets off. The engineer gets ‘em up to ten mph, and about 8 cars later … KABAMMM, right into the standing cut. Van gets on the engine. “Okay you rotten S.O.B!!, you gonna pay a little better attention”. There was no reply, but the rest of the shift and the next day he was pretty compliant.

To take care of the urination “incidents” the following unseen visitor was placed behind the control stand of the GP-7. No it wasn’t snake or a spider, it was a perceived empty spike keg.

To preface, the layout of these old cabs, the engineer is on the right-hand side. The control stand and the air brake valves, within reach just to the left. The throttle, transition lever, and dynamic brake handle( if equipped ) just ahead. Across the cab, there are two seats on the fireman’s side. One for the fireman( if you have or had one ) and one for the head brakeman. Directly behind the control stand is a door that accesses the high short hood, which holds spare air hoses, knuckles, tools and the toilet. The space behind, in between the rear cab door, and the fireman’s side window, is where the electrical cabinet, that houses the High and Low voltage relays and contactors, and electrical busses and cabling for the traction motors.

The GP 7 control stand Left to right. Top Left bottom of the communications radio. Bottom left a portion of the 24-RL automatic brake valve. Top center the rainbow looking gauge is the AMP Gauge below that is air air brake gauges and warning lights (Wheel slip-PCS Open-No Battery Charge-Engine Not Running) The electrical switches below ( Control-Generator Field-Fuel Pump-Gauge Lights-Rear class Lights-Forward class lights-Rear Headlight-Forward Headlight-Ground lights) Bottom center the SA-24 independent brake valve. The rope is for the whistle The big round white circle is the speed recorder (either a BARCO or Chicago Pneumatic) The Round looking thing is the Throttle (right handle) The opposite side Transition Lever / dynamic brake just below that is the Reverser

Since there are 4 men sometimes in the cab, and only three chairs, a spike keg or 5 gallon bucket is upturned and that becomes the fourth makeshift seat.

Remember I said in a previous entry, on the putrid smell of rotting grain or sugar beets. Any railroader who has switched in a yard, or yarded a train, has smelled this wonderful aroma. Spilled grain comes from improperly closed or leaking hopper doors. The carman will attempt to close them, or they are sent to the rip-track for repair. The Grain elevators are supposed to check to ensure the are closed, sealed, and ready for transit. There can be piles of this. The birds help themselves, and things tend to grow. It is usually maggots.

The bucket was filled half way with this wonderful concoction. This was placed directly behind the control stand. A few sheets of left over newspaper ( with a few holes made) was placed over the top. Giving an illusion that it was left on top of the makeshift seat. Its a hot and humid Texas afternoon and becoming evening. The cab, is now starting to reek.

The engineer, who is unaware, that this crap is, and has been riding with him the last four hours, finally yells out the window. “Goddamn this yard stinks”. Van and the pin puller nod and smile at each other. I asked Van if he ever caught on, or found it? “No” he calmly said, “The bucket and him were good friends, that whole eight hour shift”. Then he laughed out load. “We made sure that we took it off the engine, so the next old boy would’nt have to smell it”.

Moral of the story. Don’t make your switch crew angry or piss ‘em off!!

MageB ⋅ May 25, 2015

Yes, sir, I sure won't. LOL