Adam Traudt Machinist and the Vapor Clarkson Steam Generators in Tales of the Jointed Track

- Feb. 12, 2015, 8:50 p.m.

- |

- Public

We still worked the passenger units as needed or requested. I was going through the tops. The pipe fitters were draining the steam generators and ready to clean the scale out of the pipes. This was done each time in Denver, and they were high maintenance. The were the standard Vapor-Clarkson models

This is a color photo of a Vapor Clarkson steam generator. It is outside and looks in bad shape. Scrap material most likely.

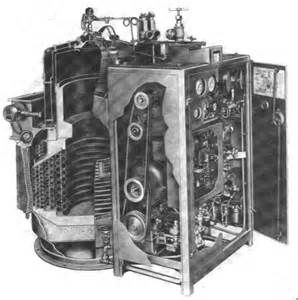

These were cleaned out with an acid wash to knock out scale build up. The tank you see on the left is the fire chamber, with a water coil assembly in the bottom. If there is blockage and the blow down separator not used at least once an hour, the coils will over heat and melt due to lack of water. That was the Fireman’s job to insure these were up and operating, the separator blow down used, make sure water is filling properly and cycling..

A cut-away drawing of the standard Vapor-Clarkson. You can see the coils, in the bottom part. Water is pumped into the coils. The fuel, is sprayed into the combustion chamber. There is an electrode on top, that fires off the atomized fuel mixture. The electrode, cycles on and off as needed. It will arc across, the the fuel is admitted in.

They would use water naturally, so there were filling stations at the depots, to replenish the supply. They were not user friendly. I did not have to operate these Per Se, because I never fired passenger. When I went into engine service with the Santa Fe, my route did not get passenger trains. Every once and a while there was a detour or a Directors Special, but Santa Fe had a Mechanical man to aid the fireman as needed. AND YES YOU THE TAXPAYER PAID FOR ANY AMTRAK WORK. You still do.

Adam Traudt…Machinist

I worked with Adam a few times , a man of not so many words. He was getting close to retirement. His son worked as a trainman and/or Yardmaster during that time frame. Adam did Steam Generator maintenance and change outs.. He made sure the regulating governors, pumps, fuel supply was where it was needed to be. He also made coil inspections, and performed the routine maintenance.

There was an E unit at the far end of Line 2. There was a ration of change outs due to melted coils. The BN and AMTRAK are not happy about the failures. We are also getting old and poorly maintained units into the passenger pool, bought from other railroads. Amtrak tried to get passenger locomotives and cars from the railroads that left the passenger train business. The railroad is getting the newer employees all crafts, so the fireman aren’t trained properly or do not have the experience. If you’re not paying attention, you’ll cause a failure in the long run. Scale and low water levels will melt those coils quicker than you think. Watch the water level and fill cycles, proper use the separator blow down to purge the coils of scale .

*two pictures of the Vapor Clarkson steam generator. *

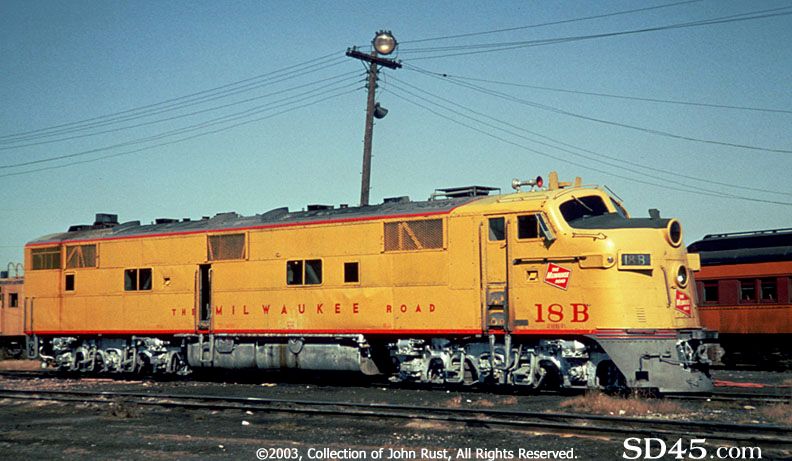

So the carbody roof was off of the rear end of the locomotive. The old steam generator was lifted out and a new one placed back in. The stacks were fitted for the outlet caps, then after it was fitted, they would be removed, and wait for the carbody roof to be placed and secured. Then the stack caps would be placed back on and secured.

You can see the rear carbody of this Milwaukee Road E-6A. The stack and steam relief blow off on top. The two “Screened” areas are the air intakes for the steam generator. The top roof area can be unbolted and lifted off with an overhead shop crane. Also the side panels can be removed as necessary.

I was told help Adam out. I helped get tools. parts, or fasteners. We bolted the generator to the floor and reattached the fuel lines. The pipe fitters fastened up the water lines and the electricians, the connections. So now for the “TEST” …

How does our handiwork pan out ? The battery switch was placed up, and the pump for the generator was energized.

Adam said, “You ever do this ?” .. “NO I haven’t” “It’s not hard. Make sure you place the switch onto fill . A light will say ready, also make sure the fuel access is on and running. Then when it says START, click the switch to FIRE”. These were all Idiot lights . Hey how did they know I was operating this???

“You ready” asked Adam. “Yes” “Okay flip it to FILL”. The pump cycled filling the coils. ” Kick the fuel pump on”. We heard the lines begin to pressurize. Adam yelled “Start it Kid”.. “Mr Traudt, the light says not ready. Do you want to check” ? “NO… place the switch to fire”.

GULP here goes . I placed the switch to fire and run.. KAABOOOM… KABOOMMMMM. Black smoke and the explosion blew the exhaust caps off. They were in orbit. They hit the top of the diesel shop. Now the roosting pigeons are scattering, people on the shop floor are getting in carbody units and/or cabs, or down below. Our missiles finally hit the shop floor with a bunch of metallic commotion. The culprit was an old fuel check valve. That was changed out and it fired off like it was supposed to. Adam never showed emotion, anger, disgust. He said “I think it will be okay now”. It was like he just planted a bed of flowers.

I hated those Vapor Clarksons, but I could make ‘em go if I needed to.

Curses in my young railroad career.. the Elwell-Parker and the Vapor Clarkson’s..

Loading comments...