J-SLE The runaway coal train in Tales of the Jointed Track

- Feb. 11, 2015, 8:53 p.m.

- |

- Public

I wasn’t involved in this, and I wasn’t on this train. I was called to shove up a train, and we were held at Sedalia, Co on the southbound. We had instructions, not to proceed past MP 24.5 via radio. This came from the Santa Fe and Rio Grande dispatchers. We found out, that a Houston Coal train, with UFIX hoppers, had run away, and derailed around MP 73.6 at the old Russina siding, or what was left of it. Luckily no one was killed or injured. Damage resulted in 40 to 50 derailed cars. The locomotives derailed as well, but broke free of the carnage, and remained upright.

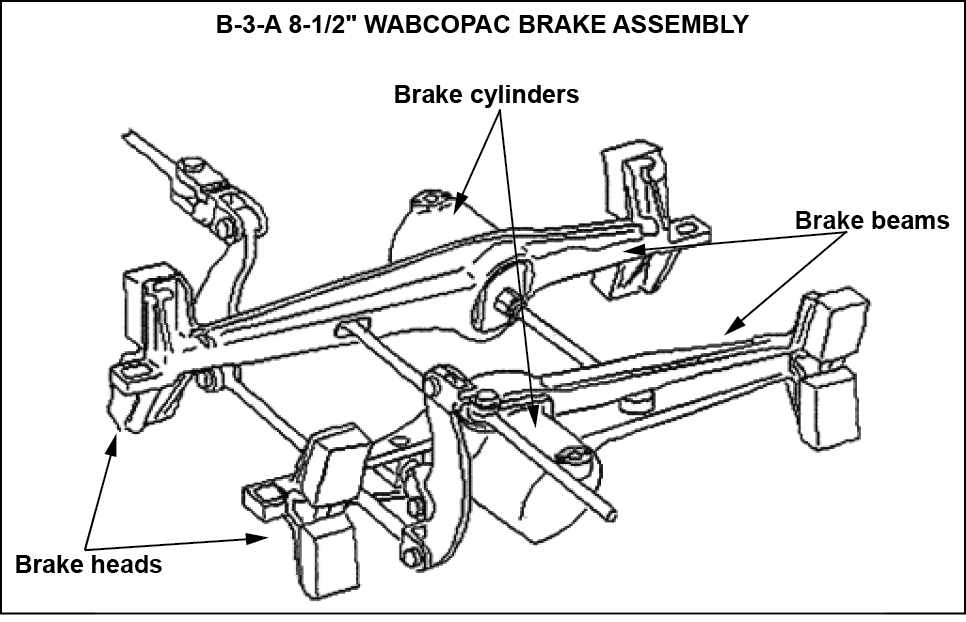

This train was bound for the Utility at Spring, TX. We have had a week or more of below zero weather. They were called for 900 or 1000 pm. The night temperatures at this time hovered in the 15 to 20 below range. The train was a standard of 125 to 127 cars 17,350 tonnage range. These were Berwick Bathtub rotary hoppers. They had truck mounted brakes, and not operated with a Rod and Lever, style system.

Typical Bathtub hopper

Schematic drawing of the WABCO truck brake system

We, locomotive engineers complained about the braking. It fell on deaf ears. Was, train handling and the engineers ability to compensate. Really, was we aren’t addressing this, because these are BN trains, and this is a young workforce. Horsecrap, sorry, I know my skills, and there are others running longer than I have sending the message.

This is the scenario, which they set themselves up for. Something I wouldn’t even consider. I learned air brakes, how and why it operates. Why it fails, why it acts, and what pitfalls to avoid. Frank Kasulas, Gordon Euell, Elvin Bethurm, Ray Redmond, Dominic Valenti, and the late Ernest F. Zumbrumm, these were train handlers and air brake artists. Ernie Z!!, well he could run the wheels off of ‘em.

They were having air problems up the hill. REALLY!! that’s a flag right there. Sticking brakes, unable to release properly,so they did a cheat. This is a big and total NO-NO. This is not DP, where the computers synchronize the the brake valves and brake pipe. This is the head end controlling the air, and the helpers have the brake valve out.

This also is a BN problem, and most likely forced out of the terminal. This is a UFIX problem, due to related concerns about the braking system. A Santa Fe problem, because the concerns weren’t taken seriously. AND I’ll lay blame overall, this operating and helper crew problem.

The helper crew, cut in the automatic brake valve. Thinking this would relieve the sticking brake problems, they created a bigger one. A false brake pipe. With the cold weather, there was a compromise. The head end charged so many, now the rear end can charge so many, and the rest, well the air equipment, is accepting signals. Strong, faint, whatever, they don’t get a good charge. The fatal glass of beer.

They cut off and run around the caboose. It’s still below zero, and the air is saying well, we will draw down, and we don’t have enough to charge properly. The brake pipe will show a good or a medium draw.

Air brake lesson:

The brake pipe charges up first, then it flows to the air brake reservoirs, via the branch pipe and air brake service portions. The cold air, and what occurred up the hill, elevated the false brake pipe.

The air was cut in, the helpers cut off, and .........

To be continued

Last updated February 11, 2015

Loading comments...